|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

NUTRACO MESINDOTAMA

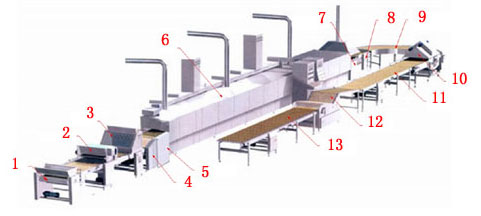

Soft Biscuit Production Line

According to the condition of the plant layouts,bend unit is used.

The oven is the important in biscuits production and adopt JB4415-88 ministry standard.The over with high technology and high efficiency is the first condition to reduce cost of production. The infrared ray electric ovenis mail composed of infrared ray heating parts(including infrared radiation implement or quartz pine), oven conveyer device, moisture discharging and electic control system. Main characteristics: 1)high efficiency and energy saving:the radiation is concentrated and the rate is over 95%. The resuit of power saving is over 35% and it has long service life. The even radiation energy of quartz pipe can reach 30% of power saving effect and it needs small investment. 2)the design of oven is special and heat preservation performance can surpass state standard. 3)adopt silicon controlled rectifier voltage and control the oven temperature automatically. Main Reference Data :

The equiprent is used as transition from OVEN to SPRAYER OIL MACHINE Mail Technical Parameter :

The machine adopts most advanced centrifugal device in the world.The centrifugal wheel revolves so fast that the oil on the wheel gain very great centrifugal force and atomized oil biscuit.The eight group of oil-spray device can regulate the volume and temperature of oil automatically and freely.This machine have the characteristics of low noise,energy saving,fine design,easy operstion and health.

The color,fragance and flavor of biscuits are greatly improved after oil spray So it's absolutely necessary equipment for biscuit upgrading. Main technical parameter: Total power:5kw Working voltage:220v 50Hz Speed:5-20m/min When spray oil:1-5kg/min

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Created by CAIRON SUPRA Copyright © 1995 - 2025 PT NUTRACO MESINDOTAMA. All Rights Reserved.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The function of machine is spreading the grains of salt, sugar and sesame evenly on the surface of biscuit, which increase it's characteristics and flavor. There's facility to take back the remain material in the machine. It's an indispensable equipment to increase biscuits kinds.

The function of machine is spreading the grains of salt, sugar and sesame evenly on the surface of biscuit, which increase it's characteristics and flavor. There's facility to take back the remain material in the machine. It's an indispensable equipment to increase biscuits kinds. Spray liquid of egg,it can improve the biscuit's taste and odour.It make the seasame,unt,almond can paste more firm.

Spray liquid of egg,it can improve the biscuit's taste and odour.It make the seasame,unt,almond can paste more firm.

This is an auxiliary equipment that make full use of factory building. When the length of workshop is not enough, backed biscuit can make a 90 or 180 plain turn and make a transitional carry different disposition can be provided according to customer's requirements.

This is an auxiliary equipment that make full use of factory building. When the length of workshop is not enough, backed biscuit can make a 90 or 180 plain turn and make a transitional carry different disposition can be provided according to customer's requirements.  This machine can sorting the biscuit. it make sorting, withdrow, pile carry convenient.

This machine can sorting the biscuit. it make sorting, withdrow, pile carry convenient.