|

|

|

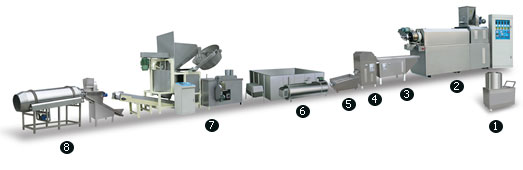

Screw / Shell / Processing Line

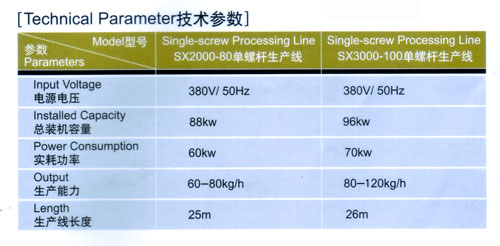

Technical Parameter

| Power |

3kw |

| Speed |

365RPM |

| Throughput |

20kg per loading (5 minutes per loading) |

| Dimension |

1000*500*800mm |

This equipment can mix floury, grainy material; it’s the first step of food processing. It use "? shape mixing method, drive by a electromotor, mainly using for mixing raw material, water and addictives. Raw material mixed fast and evenly.

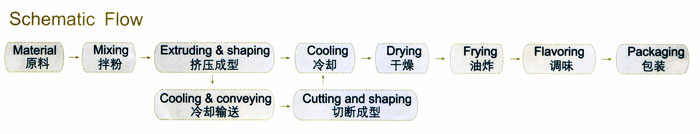

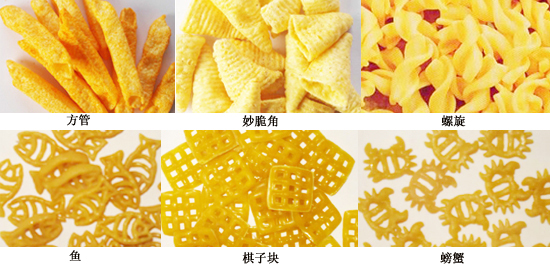

This equipment is made up of feeding system,extruding extruding system,cutting system,heating system,driving system,cooling system,usually fit for frying food.

Feeding system,drive system and cutting system adopts inverter speed controlling,strong motivity,steady running.

Screw,barrel,moulds adopt circulating cooling system to make sure that when the raw material through extruding,the temperature is steadier.

According to different material,to choose the relative single or double screw feeding system,the material should be uniformity and stable.

The extruder-screw processed by special ethnics,wearable,resisting of tire and microbial.

According to different material and product character,use many screws machine barrels of different length combination and finish manifold extruder experiments.

Technical Parameter

| Model |

Installed Power |

Actual Consumption |

Main Power |

Throughput |

Dimension |

Products |

| SX75-VII |

13.5KW |

10KW |

7.5KW |

60KG/H |

1.8x0.7x1.56M |

Rice crust/Soup frying food |

| SX2000-75 |

38KW |

25KW |

22KW |

30-50KG/H |

3.0x1.2x1.7M |

Second inflating food |

| SX2000-80 |

38KW |

28KW |

22KW |

40-50KG/H |

3.0x1.05x1.96M |

Second inflating food |

| SX3000-100 |

54KW |

30KW |

38KW |

80-100KG/H |

3.2x1.05x1.96 |

Second inflating food |

This equipment is widely used,fits for frying various inflating snack food and nut.Controlling system adopts import programme parts.Automatically adjust the temperature,mix,deoil and convey.

Main Features

1 Oil can flow inside the tunnel ensure oil temperature is steady.

2 Oil can flow inside the tunnel ensure oil temperature is steady.

3 Startup automatic rising system,convenient to clean and maintain.

4 Large output,low consumption,saving cost.

Technical Parameter

| Model |

Input Voltage |

Throughput |

Dimension |

| YZD-II |

380V/50Hz |

100-150KG/H |

4.55x1.98x2.9M |

| YZY-II |

380V/50Hz |

60KG/H |

4.55x1.98x2.9M |

Main features:

1 Materials will be in the roller automatically through elevator.

2 There is a flavoring quantity control device on the roller, make sure flavor spread evenly on snacks.

3 Rotary roller adopts complete molding, no dead angle inside.

4 Oil spray nozzle can adjust the oil amount, spraying equally.

Technical Parameter

| |

single roller |

double roller |

eight square roller |

| Model |

TWD-I |

TWS-I |

TWB-I |

| Throughput |

150—200KG/H |

180—250KG/H |

150—200KG/H |

| Power |

0.37KW |

0.74KW |

0.37KW |

| Dimension |

2.1x0.7x1.6M |

3.6x0.9x1.7M |

1.4x1.1x1.6M |

|