|

|

|

NUTRACO MESINDOTAMA

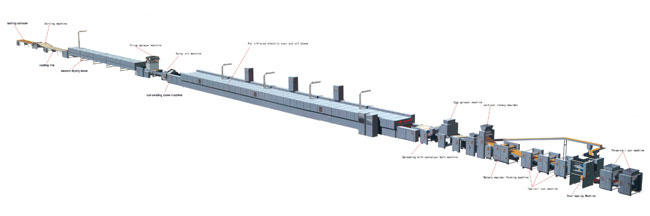

Soft / Hard Biscuit production line

1. Process

three roll-cut machine→three-cut machine→overlapping machine→two roll-cut machine→ two roll-cut machine→two roll-cut machine→ rotary moulder machine→transition machine→separating machine →vertical/horizontal rotary moulder→transition machine→egg sprinkler→spreading machine with conveyer belt →into-sending stove machine(with salt and sugar gather)→oven→out-sending stove machine→sugar sprinkler→oil sprinkler→second drying stove → cooling line→sorting machine→sorting console

2. Main characteristic:

- This is a multifunctional project to produce soft , hard biscuit project.It is suit to produce all kinds of soft , hard biscuit,biscuit with filling, soda biscuit,double color biscuit, thinnest biscuit and supper thinnest biscuit etc.

- the three-cut machine can be used with overlapping machine together.This assembled project can produce threecolor biscuits or biscuits with filling.If only use the overlapping machine ,we can produce all kinds of hardand soda biscuits.

- To produce soft biscuit only need to start up vertical/horizontal rotary moulder and its latter equipments;

- Remainder reclaimer by side is used to gather the remainder from separating machine into the hopper of the feedingmachine.

- Egg sprinkler and spreading machine with belt is used to increase the types of the production.

- the latter dealings with the biscuits are including :spraying oil and spraying eggs,these are ideal equipments to increase biscuits types and improve production;

- The assemble of sugar sprinkler and second drying stove are optional,these two can be used as transmition and cooling equipment;

- Sorting machine stacks and sorts the biscuits from the transmition and cooling machine to make them in order.

3. Remark:

vertical rotary moulder is suitable for the plant where the flour be mixed on the second floor ;If the dough mixer is fixed in the different floor from the production line,horizontal rotary moulder should be used.

Main technical parameter :

| Type |

Output |

Dimensions(L×W×H) |

| HW-600 |

600kg/h |

117180×1900×2625mm |

| HW-1000 |

1000kg/h |

154180×2300×2625mm |

|