|

|

|

NUTRACO MESINDOTAMA

Automatic Feeding Packaging

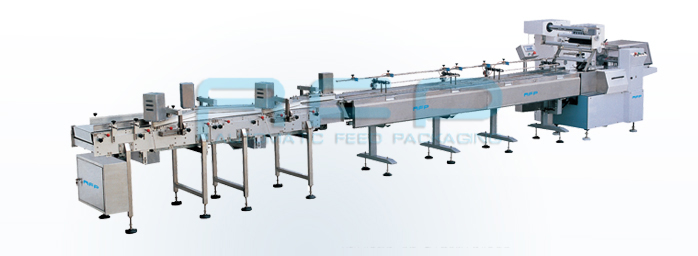

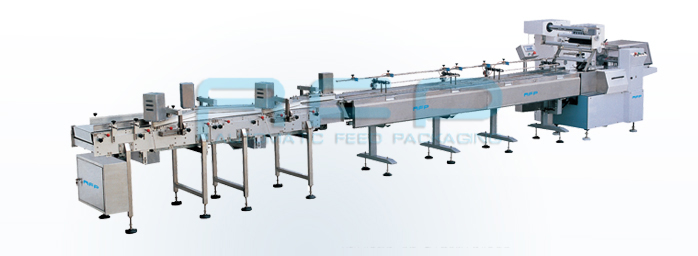

1. FS 1000 Automatic Feed Packaging Lines

Model NO.: FS1000

Trademark: AFP

Origin: China

Product Description

Product performance:

1 Applicable to the food which have regular arrangement on the production line. (such as the Swiss roll, cake, chocolate or those which contain fillings or other individual regular food )

2 Multi-layer packaging or multi-parallel in one sachet can be achieved by changing the feeding machine.

Prominent advantages:

1 Quantity (2 to 8) is decided by the unit output of production line and unit packing speed of the packing machine.

2 The whole process from distribution, arrangement, turning, positioning to packaging is finished automatically, which need no manual operation.

3 It can arrange products which are not in cleaning-up condition in good order automatically.

4 To ensure materials distributed regularly and averagely by way of swinging the feeding-hopper.

Structural features:

1 Simple structure makes the machine easy to clean, also it ensures food safety and hygiene.

2 Wide conveyor belt has the function of automatic eccentricity regulation, and is convenient to assemble and dismantle

3 High-quality components are adopted to ensure reliable performances of the line.

2. Automatic Feed Packaging Lines (KZ150).

Model NO.: KZ150

Productivity: 150 pcs/min

Product Description

Product performance:

» The feeding line is applicable to French bread and Custard cake.

» Auto-feeding and packing speed is up to 150 pcs/min (depend on products or packing materials).

» Connected to production line, the whole process is fully automatically completed from feeding to packaging.

» The feed line can match not only Kezhen KZB250 packaging machine, but also other packaging machines manufactured by different enterprises.

» The wrapping machine can be equipped with automatic filming device, printing device or inflating device.

Prominent advantages:

» The auto-feeding machine and packaging machine work in synchronization, such as Synchronous change, automatic stop/startup in case of material absence/supply, to minimize manpower operation.

» To minimize secondary pollution of products due to traditional manpower handling.

Structural features:

» The auto-feeding packaging machinery is in simple and vivid structure.

» All conveyor belts can be assembled and dismantled quickly without using any tools.

» Easy for cleaning, to ensure food safety and hygiene.

3. Automatic Cutting Feed Packaging Lines (KZ180)

Product Description

Product performance:

» Applicable to waffle, biscuit and sandwich or products of similar shapes or features.

» Auto-feeding and packaging speed is up to 150-180 pcs/min (depend on products or packing materials).

» To realize secondary cutting, feeding and packing automatically without manual operation.

» The feeder machinery can match not only Kezhen KZB250 packing machine, but also other packaging machines manufactured by different enterprises.

Prominent advantages:

» It is so simple that the operator is only required to put the large cakes after first cutting on the cutter in piles, and the remaining works will be finished by the machine.

» Manpower is greatly reduced, especially to the packaging of double-layer fragile cakes and the damage ratio is minimize. The secondary pollution caused by manual operation is avoided.

Structural features:

» Simple and vivid structure.

» All conveyor belts can be assembled and dismantled quickly without using any tools.

» The wrapping line is easy to clean to ensure food safety and hygiene.

» High-quality components are adopted to ensure reliable performances of the feeding line.

4. Filling system by volumetric dosage

Product Description

Product performance:

» The feeding line is applicable to cylindrical /rod-shaped foodstuff products.

» Auto-feeding and wrapping speed is up to 200 pcs/min (depend on products or packing materials).

» Independently working, only when the products are put to the feeding entrance, and the whole process from handling, feeding and the packaging will be finished automatically without manual operation.

» The automatic wrapping line can match not only Kezhen KZB250 packing machine, but also other packing machines manufactured by different enterprises.

Prominent advantages:

» It is so simple when the products are put to the feeding entrance. And the whole processes from handling, feeding and the packaging will be finished automatically without manual operation.

» To minimize secondary pollution of products due to traditional manual operation.

Structural features:

» Simple and vivid structure.

» All conveyor belts can be assembled and dismantled quickly without using any tools.

» Easy to clean to ensure food safety and hygiene.

5. Automatic Feed Packaging Lines (KZ250)

Model NO.: KZ250

Productivity: 250 pcs/min

Product Description

Product performance:

»The automatic feeding line is applicable to rectangular, square or circular food products(eg candy, pastry, buscuit, chocolate, sachima etc).

»Auto-feeding and packaging speed is up to 250 pcs/min (depend on products or packing materials).

»To realize automatic feeding and packaging without manual operation.

»Can be connected not only to automatic production line, but also to semi-automatic conveyor belt feeding.

»The feeding line can match not only Kezhen KZB250 packaging machine, but also packaging machines manufactured by different enterprises.

»The packing machine can be equipped with automatic filming device and printing device.

Prominent advantages:

»Auto-feeding machine and wrapping machine work in synchronization, such as synchronous change, automatic stop/start up in case of material absence/supply, to minimize manual operation.

»Labor resource and cost are greatly reduced, and the management is greatly simplified, secondary pollution caused by traditional manual operation of products was avoided.

Structural features:

»Simple structure, stainless steel appearance.

»All conveyor belts can be assembled and dismantled quickly without using any tools, and the wide conveyor belts have the function of automatic eccentricity regulation.

»The feeding line is easy to clean to ensure food safety and hygiene.

»High-quality components are adopted to ensure reliable performances of the line.

|